Cogeneration Division

DBS »

What Is Cogeneration?

- Producing heat and electricity simultaneously is called cogeneration (mCHP – Micro Combined Heat and Power).

- To decrease energy consumption and adhere to international environmental rules and regulations, one solution is mCHP.

- mCHP is best suited for multi-residential consumption profiles.

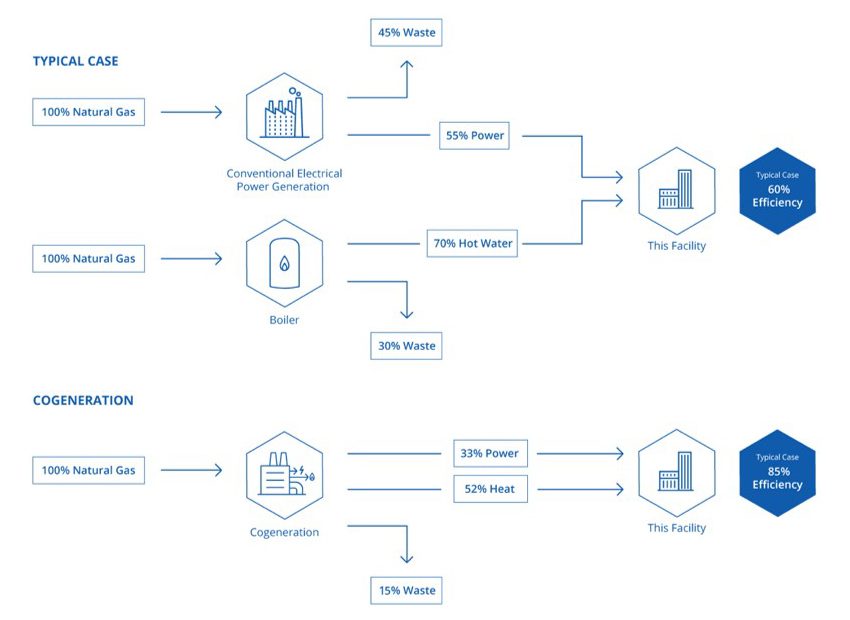

- Due to the utilization of the thermal output (heat) from the generation process, the efficiency of current devices can be as high as 85-95%.

- Ontario is ideally suited for a long system run time, as the thermal output all but eliminates the need for supplemental heating.

Two 35KW CHPs installed on the rooftop of a multi-residential apartment building

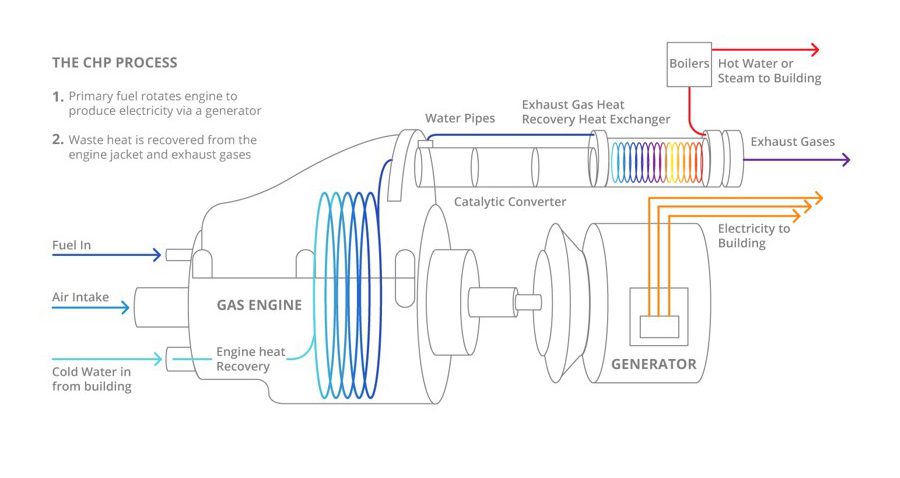

How mCHP Works

mCHP Is Economical

- Improves overall energy efficiency and fuel utilization

- Reduces electricity costs

- Reduces natural gas heating cost

- Offers high reliability and full control over the generation

- It comes in all sizes to meet low and high demand users

mCHP Is Environmentally Sound

- Produces lower emissions compared to separate power and heat production

- Meets and/or exceeds all international environmental standards

Cogeneration Benefits

Operational

- Reduced electrical supply from the utility

- Additional security and reliability of electricity

- Greater efficiency in heating and hot water consumption

- Choice of multiple fuels

- Cooling provision using absorption chillers

Financial

- Reduced primary energy costs – typically 70%

- Zero capital outlay option

- Reduced investment surrounding the plant (e.g., Boilers)

- Eligible for Enhanced Capital Allowances

- Sufficient savings to fund energy-efficient measures

Environmental

- Reduced primary energy use

- Reduced C02 emissions

- Reduced transmission losses from the grid

- Highly efficient – up to 95%

Three Steps to a Successful mCHP Installation

Choose a Company with Experience

Some companies might assemble teams with the right engineering disciplines, but nevertheless, these teams have never had the practical experience of engineering, installing, and commissioning a CHP system. Over the years, we have seen some unfathomable things, from improperly sized electrical panels to expensive and unnecessary copper pool water piping.

Don’t be a guinea pig for an mCHP company. Visit their past project sites and validate their customers’ experiences. Don’t make a decision based on a spreadsheet alone!

Look at the Whole Project

Who Will Do the Maintenance

After the project is complete, your only relationship remains with a maintenance organization that will maintain your mCHP unit and associated equipment. It is also important to adequately consider the maintenance process during design to make sure that the system can be easily maintained throughout its life.

Next, you will want to understand the history of the company handling the maintenance. Here are some questions to ask:

– What experience do they have with the equipment and setup that you’ve just had installed?

– Are they licensed and qualified?

– Do they stock parts inventory?

– Do they have a history of customer satisfaction?

– What will your maintenance provider do when something breaks?

– What are their service level agreement timelines?

At DBS, we have a fleet of 60 trucks always ready to service our customers. Plus, we’ve added controls to our procedures; we can either make a fix remotely or make sure that the service technician is prepared with the right parts before he even heads to the site for a diagnostic.